- Products

-

- VSD Wiki

- Contact us

VSD manufacturers

sales@VariableSpeedDrive.co.za

Tag:

Hoist machine is one of the most power-consuming and important equipments in mine. Its reliability influences production and personnel safety directly. Meanwhile, speed adjustment mode of Hoist machine is also a big factor for power consumption.

For long term, Hoist machine adopts rotor series resistance to adjust speed. It is low cost but with big torque, high consumption and complicated circuit. It damages contactor, resistor and electrical brush easily, which threatens system safety. With rapid development of power and motor technology, variable speed technology can solve above problems.

Operation performance of variable speed adjustment

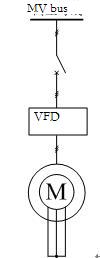

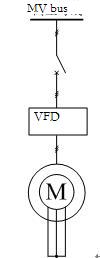

Short connect rotor winding of motor, convert power frequency voltage to voltage of some frequency through electrical components inside variable speed drive and the voltage is applied to stator winding of motor. It controls motor to run in expected speed by adjusting output voltage, frequency and phase position. Its circuit is shown following:

Compared with mode of rotor series resistance, variable speed technology has advantages of small current, stable motor operation, small torque pulsation, high controllability and energy saving.

Main control methods of variable speed technology are VVVF control, slip differential frequency control, direct torque control and vector control. vector control can realize decoupling control of magnetic flux and torque by modeling for motor, with the best control performance. Gozuk variable speed drive introduced in this paper adopts vector control. It is applicable for Hoist machine as its good control performance.

In vector control, variable speed drive can calculate magnetic-flux position, magnetic-flux amplitude, output torque and motor speed according to voltage signal, current signal, motor parameters and motor modeling. Then according to deviation of this speed and given speed, it adjusts output torque. If output torque is more than given "max torque", it outputs max torque.

For long term, Hoist machine adopts rotor series resistance to adjust speed. It is low cost but with big torque, high consumption and complicated circuit. It damages contactor, resistor and electrical brush easily, which threatens system safety. With rapid development of power and motor technology, variable speed technology can solve above problems.

Operation performance of variable speed adjustment

Short connect rotor winding of motor, convert power frequency voltage to voltage of some frequency through electrical components inside variable speed drive and the voltage is applied to stator winding of motor. It controls motor to run in expected speed by adjusting output voltage, frequency and phase position. Its circuit is shown following:

Compared with mode of rotor series resistance, variable speed technology has advantages of small current, stable motor operation, small torque pulsation, high controllability and energy saving.

Main control methods of variable speed technology are VVVF control, slip differential frequency control, direct torque control and vector control. vector control can realize decoupling control of magnetic flux and torque by modeling for motor, with the best control performance. Gozuk variable speed drive introduced in this paper adopts vector control. It is applicable for Hoist machine as its good control performance.

In vector control, variable speed drive can calculate magnetic-flux position, magnetic-flux amplitude, output torque and motor speed according to voltage signal, current signal, motor parameters and motor modeling. Then according to deviation of this speed and given speed, it adjusts output torque. If output torque is more than given "max torque", it outputs max torque.

Tags: Mining industry

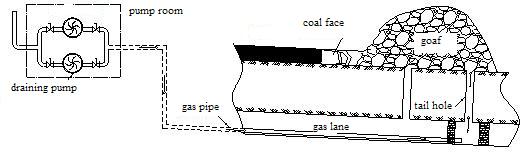

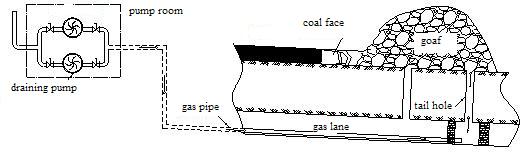

There is a drain pipe of diameter 1000mm which is in gas lane of goaf bottom and comes to pump room. Pump is water ring vacuum pump. Please see technical diagram in following:

Here are parameters:

Pump parameters

Rated speed: 340r/min

Max drain flow: 635m3/min

Ultimate vacuum: 160MPa

Motor parameters

Rated power: 900kW

Rated voltage: 6kV

Rated current: 104.2A

Rated speed : 1483r/min

Power factor: 0.87

Here are parameters:

Pump parameters

Rated speed: 340r/min

Max drain flow: 635m3/min

Ultimate vacuum: 160MPa

Motor parameters

Rated power: 900kW

Rated voltage: 6kV

Rated current: 104.2A

Rated speed : 1483r/min

Power factor: 0.87

Tags: Mining industry