Variable speed drive on fan for air flow control

At present, competition is very intense. The key is cost. Power consumption of motor accounts for 30% of cost. Motor driving fan is a big part. So it is very important to reduce consumption of motor. Today, phenomenon of "large horse drives small dolly" is serious. If technology of variable speed is adopted, it not only satisfies production requirement but also saves energy. Meanwhile, variable speed drive saves a lot of energy source and improves efficiency for plant. After innovation with variable speed drive, energy saving rate is in 30-50%. The investment usually recovers in one or two years.

Problems in baffle control mode

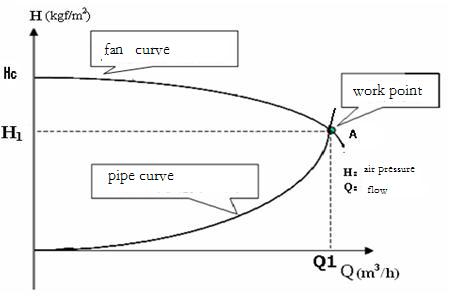

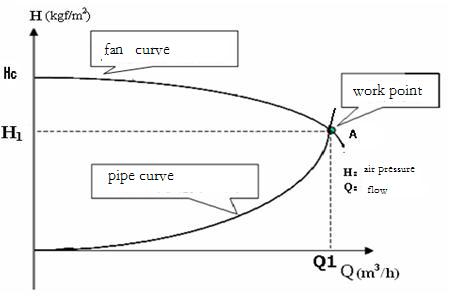

Conventionally, air flow is controlled by valve opening. This is a behindhand method with inferior economic benefit, much consumption, serious damage, difficult maintenance and high cost. Fan performance is shown following:

Work in direct on line state

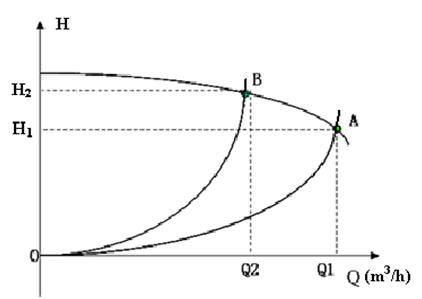

It indicates pump character curve keeps unchanged, change network curve. Usually, keep fan curve unchanged (not change fan speed), change outlet by valve to change air flow. As the drawing:

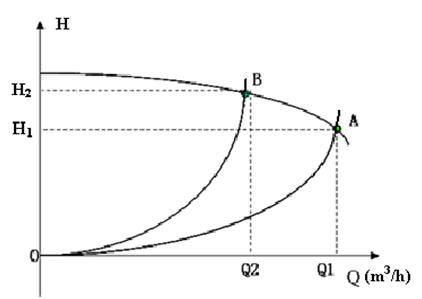

When fan works in A, air flow is Q1,pressure is H1. Keep fan speed constant, adjust air flow to Q2 by baffle. Pressure will rise to H2, fan work point is B. Because of baffle throttle, resistance curve of duct is changed to OB.

When fan works in A, its power is PA=H1×Q1/102;when in B, its power is PB=H2×Q2 /102.

Q2<Q1, but H3>H1,so PA PB do not change a lot. It indicates that in direct on line state, shaft power of fan reduces little when air flow is changed.

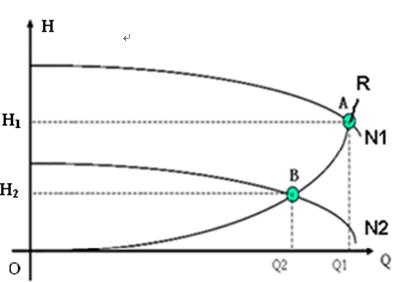

Work in variable speed state

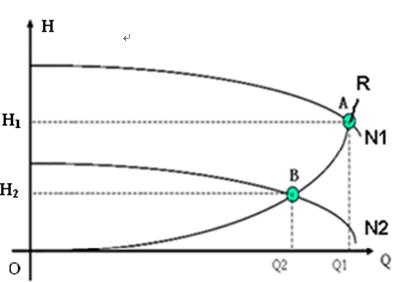

It indicates network curve keeps unchanged, change fan curve. Usually, do not change fan outlet, change fan curve (change fan speed) to change air flow.

When fan works in A, its power is PA=H1×Q1/102;when in B, its power is PB=H2×Q2/102.

Q2<Q1,H2>H1,so PA PB change a lot. It indicates that in variable speed state, shaft power of fan reduces a lot when air flow is changed. Energy saving is considerable.

The relations:

Output flow Q and speed n:Q1/Q2=n1/n2…… (1)

Output pressure H and speed n:H1/H2=(n1/n2)2 …… (2)

Output shaft power P and speed n:P1/P2=(n1/n2)3…… (3)

If 100% speed -100% flow -100% pressure-100% output power,there is: 80% speed- 80%flow- 64% pressure- 51% output power. Namely, in variable speed state, when flow reduces 20%, shaft power reduces 49%. That is the reason why variable speed drive has a considerable energy saving effect.

Application in Cement Plant

1. Instruction

A high temperature fan in 5000t/d production line needs reform with variable speed drive. At present, air flow and pressure are controlled by valve and liquid coupling. But there are following problems in site:

2. Site data

(1) motor and liquid coupling

(2) average price: 0.5yuan/kWh

(3) annual time: T=8000h

3. Comparison

Advantages

Baffle control has disadvantages of much consumption, inferior economic benefit and bad damage. Technology of variable speed can reduce consumption and heighten economic benefit. The practice proves that variable speed drive is necessary, feasible in cement plant and has considerable economic benefit.

Problems in baffle control mode

Conventionally, air flow is controlled by valve opening. This is a behindhand method with inferior economic benefit, much consumption, serious damage, difficult maintenance and high cost. Fan performance is shown following:

Work in direct on line state

It indicates pump character curve keeps unchanged, change network curve. Usually, keep fan curve unchanged (not change fan speed), change outlet by valve to change air flow. As the drawing:

When fan works in A, air flow is Q1,pressure is H1. Keep fan speed constant, adjust air flow to Q2 by baffle. Pressure will rise to H2, fan work point is B. Because of baffle throttle, resistance curve of duct is changed to OB.

When fan works in A, its power is PA=H1×Q1/102;when in B, its power is PB=H2×Q2 /102.

Q2<Q1, but H3>H1,so PA PB do not change a lot. It indicates that in direct on line state, shaft power of fan reduces little when air flow is changed.

Work in variable speed state

It indicates network curve keeps unchanged, change fan curve. Usually, do not change fan outlet, change fan curve (change fan speed) to change air flow.

When fan works in A, its power is PA=H1×Q1/102;when in B, its power is PB=H2×Q2/102.

Q2<Q1,H2>H1,so PA PB change a lot. It indicates that in variable speed state, shaft power of fan reduces a lot when air flow is changed. Energy saving is considerable.

The relations:

Output flow Q and speed n:Q1/Q2=n1/n2…… (1)

Output pressure H and speed n:H1/H2=(n1/n2)2 …… (2)

Output shaft power P and speed n:P1/P2=(n1/n2)3…… (3)

If 100% speed -100% flow -100% pressure-100% output power,there is: 80% speed- 80%flow- 64% pressure- 51% output power. Namely, in variable speed state, when flow reduces 20%, shaft power reduces 49%. That is the reason why variable speed drive has a considerable energy saving effect.

Application in Cement Plant

1. Instruction

A high temperature fan in 5000t/d production line needs reform with variable speed drive. At present, air flow and pressure are controlled by valve and liquid coupling. But there are following problems in site:

- Disadvantage of liquid coupling: efficiency is lower with speed reducing. Installation needs cutting off connection of motor and load. Site is dirty and needs much maintenance.

- With water resistance, there is still 3 times of rated current to impact grid. And water resistance starts slowly, which makes water boiling.

- It has large throttle loss and low inlet pressure, low efficiency with valve control.

2. Site data

(1) motor and liquid coupling

(2) average price: 0.5yuan/kWh

(3) annual time: T=8000h

| Motor | Fan | Hydraulic coupling | |||

| Rated power | 3200kW/10kV | Rated flow | 828000m3/h millstones open | Speed adjusting | 192-960 r/min |

| Rated speed | 993r/min | Rated flow | 687000m3/h Millstones close |

|

|

| Rated current | 219.3A | Static pressure | -7500Pa |

|

|

| Power factor | 0.876 | Rated speed | 912r/min |

|

|

3. Comparison

|

|

Before | After |

| Average consumption | 2701kW | 2152.6kW |

| Start mode | Water resistance | Soft start |

| Fan surge | Yes | No |

| Bearing temperature | High | Low |

| Energy saving rate | - | 20.3% |

Advantages

- By soft start, start current is smaller than rated current. Start is more smooth.

- Improve efficiency, eliminate throttle loss.

- Process technology is improved and equipment lifetime is prolonged.

- After reform with variable speed drive, 41 down harmonic can be eliminated because of cell-cascade. Total voltage harmonic is controlled in 2%. Total current harmonic is less than 4%.

- PWM control makes output voltage waveform near sine. Total harmonic is less than 1%. Above indexes all satisfy IEEE-519 standard.

- Voltage source instruce, power factor can be 0.95.

- Noise lowers a lot.

Baffle control has disadvantages of much consumption, inferior economic benefit and bad damage. Technology of variable speed can reduce consumption and heighten economic benefit. The practice proves that variable speed drive is necessary, feasible in cement plant and has considerable economic benefit.

<- - I have an Opinion - ->